The Business Case for Battery Monitoring

In a power critical environment (Tier 2 upwards)

it is essential to know the state of health of the

lead acid batteries supporting the critical load.

In a power critical environment (Tier 2 upwards)

it is essential to know the state of health of the

lead acid batteries supporting the critical load.

Despite the cutting edge technology which

resides inside today's UPS systems, when a

building's AC power fails, the UPS needs to

draw its power from banks of lead acid

batteries to feed the critical load until it is able

to start and synchronize the standby generators.

There is a strong business case to be made for

investing in a state-of-the-art battery monitoring

system to manage these assets and ensure that

critical batteries are in a good state of health

and will function when required. The business

objectives include:

- Minimize the likelihood of unplanned

downtime

- Reduce costs

- Increase operating efficiency

- Improve budgetary controls and spending

Until such time as these critical batteries are

required they are typically kept in a state of full

charge to ensure the maximum run time when

called upon (typically 5 to 25 minutes). The fact

is most UPS power failures are not due to UPS

problems but actually are due to battery failure.

In many cases valve regulated lead acid (VRLA)

batteries can fail within just a few days. (See

graph below.)

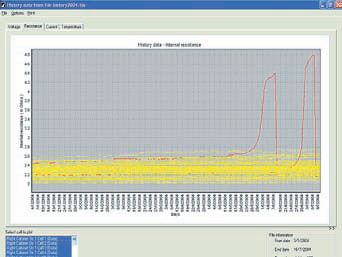

(This real world example shows the daily ohmic value of

two cabinets of VRLA batteries. The two red lines indicate

the failure of two of these jars over the course of just a few

days. Only daily ohmic measuring can show these results

in such detail.)

The most modern battery monitoring systems

have been specifically designed to monitor the

ohmic value of all of the jars every day. They

can do this because of the very light test load

used, combined with superior electrical noise

filtering techniques. Such systems can also

monitor generator start batteries that are often

neglected until needed.

A battery monitoring system can:

- Provide a "window on your battery" with

its continuous, accurate monitoring and

alarm notification.

- Provide clear information in the form of

graphs for forensic analysis.

- Reduce manpower demands and increase

safety during maintenance.

- Allow extended life of the batteries

through efficient and rapid preventative

maintenance.

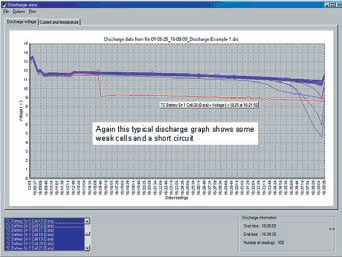

The graph below shows what such a system

automatically records when any discharge takes

place.

(This real world example of a 30 minute witness discharge

test clearly shows one bad (shorted) cell and several weak

cells within the strings—these cells were immediately

replaced.)

Cost justification on a disaster recovery

basis

For most major data-oriented businesses today,

unplanned downtime is to be avoided at all

costs and is typically a major subject in any

company's disaster recovery plan and Mean

Time To Recovery (MTTR) calculations.

It is assumed here that the reader knows the

full costs and implications of his own company's

downtime but for purposes of this discussion

here are some typical known business

statistics:

Brokerage Operations - $8 million per hour

Credit Card Sales - $3.5 million per hour

Pay per View - $200 thousand per hour

Home Shopping - $150 thousand per hour

Catalog Sales - $100 thousand per hour

(Data courtesy "Media Disaster Recovery Reaction" 2003)

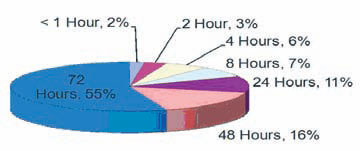

The graph below shows the likelihood of a

company going out of business in relation to the

time they are not functioning due to an

unplanned outage.

(Data courtesy "Contingency Planning Research)

So, it can be seen the cost of any outage within

a critical installation can be highly expensive at

best. At worst, the entire business is in peril.

The benefits of having a modern battery

monitoring system:

Managing the assets of a data center with a

modern battery monitoring system provides a

number of benefits. A system that provides daily

ohmic value readings can:

- Greatly reduce the risk of unplanned

downtime due to battery failure.

- Reduce the workload for the maintenance

team, increase battery and workforce

efficiency and provide the proper

management of very large numbers of

batteries.

- Ensure that the entire battery system is available by monitoring generator start

batteries.

- 4. Through continual automatic information

gathering provide

- Good clear baseline readings during

acceptance test.

- Clear decisions on warranty claims.

- Performance information during

unplanned outages.

- Provide immediate notification of detected

faults.

- Ensure that future battery replacement is

carried out in a properly timed and

budgeted manner.

- Improve health and safety conditions for

personnel tasked with battery

maintenance.

The risk of not having battery monitoring

Any power backup system that does not take

into consideration the condition of the batteries

within it is incomplete and as such the risk of

failure of the entire system due to an

unforeseen battery failure is very real.

Furthermore, as well as being impossible to

determine the probability of battery uptime

when required, it is also not possible to manage

this expensive battery asset correctly, resulting

in batteries either being replaced too late

(unplanned downtime) or too early

(overspending and with negative environmental

implications).

Meeting the business objectives

A state-of-the-art battery monitoring system

requires a small initial investment of capital and

training. But once installed and used properly,

such a system readily meets the business

objectives listed at the beginning of this article:

- Minimize the likelihood of unplanned

downtime. The battery monitoring systems

helps ensure that the standby batteries,

including the generator batteries, are

functioning and at full power when

needed.

- Reduce costs. In addition to helping

prevent the cost of unplanned downtime,

the battery monitoring system reduces the

requirements for ongoing maintenance.

- Increase operating efficiency. With

advanced knowledge of battery conditions

and possible failure, the data center

manager can avoid schedule disruptions,

deploy technicians more effectively and

even monitor remote sites without

dispatching personnel.

- Improve budgetary controls and spending.

Ongoing maintenance and battery

replacement become more predictable.

Failing batteries can be replaced while still

under warranty. Instead of bulk

replacement after two or three years, the

data center can safely keep batteries

much longer, replacing only the ones that

are starting to fail.

In terms of asset management, cost reduction

and efficiency of operation there is a strong

business case for battery monitoring.