The Prescient Data Center Manager

How to predict standby battery life.

Today’s modern UPS systems employ cutting edge

technology, and it is tempting to believe that

deploying that technology is enough to protect

mission-critical applications from a power outage. But

here’s a simple truth: the UPS draws its power from banks

of lead acid batteries, and those batteries can go from

good to failing in a matter of days. Even the latest and

greatest UPS system provides no protection without fully

functioning batteries.

There are a number of ways to manage and maintain

the batteries. The available labor resources, cost, and the

importance of the load the batteries support all influence

an organization's choice of techniques.

Labor resources not only include the amount of labor

available but the quality of that labor and other cultural

concerns. For instance, in some nations labor is plentiful;

battery maintenance and monitoring often is carried out

continuously and by hand. In some of these regions, the

staff is reluctant to bring bad news to a manager, especially

if the messenger was supposed to maintain the prematurely

failing batteries. In other societies, organizations

cannot afford a staff to continuously monitor batteries.

Most professionals would like to be able to see into the

future to know when their batteries would fail. Instead

many companies replace 10-year life batteries every three

to five years. They try to anticipate the failure of their

batteries; they try to peer into the future. A review of

battery monitoring and maintenance methods shows that

professionals do have the ability to look at historical data

right through to looking at predictive data.

Historical Failure Rates

Organizations that keep good records know the age of a

battery that dropped a load, dumped the prime web site,

lost customer dollars, lost a client, and cost someone a

job. Battery replacement is based on the principal that new

batteries should be installed just before the age they were

when they failed last time. But what happens if the data is

not available?

Checking batteries once a year tests to see if the battery

failed during the preceding 12 months. This is looking into

the past to try to avert future problems. A lead-acid battery can go from useful to useless in less time than it takes to

order up a replacement and schedule the people to come

out and fit it.

Valve-regulated, lead-acid (VRLA) batteries often cannot

take the load at time of install. Some of these batteries

recover over the first three months of life, sometimes they

just don’t. Others fail in a matter of 10-15 days during the

remainder of their life. Scheduling more frequent testing

is little help, as they could start to fail the day after the test

and be useless in time of need, two weeks later.

Also consider the nature of the test. The portable handheld

tester has a number of shortcomings. The condition

of the cables used, or more specifically, their state of

repair can affect the result considerably. Many working

and good batteries have been replaced by accident instead

of replacing the test leads. How the cable connectors are

put on the terminals also affects the results, either way.

These days many VRLA batteries do not have connection

terminals big enough to accommodate a test clip.

The quarterly visit can introduce other problems. Some

refer to the routine maintenance schedule as planned

destructive maintenance, because equipment that is working

perfectly well can be affected by tampering during

maintenance. Frequently (more often than most battery

technicians would like to admit) breakers get left open,

intercell straps are left off, plugs are left open and bolts

left finger tight.

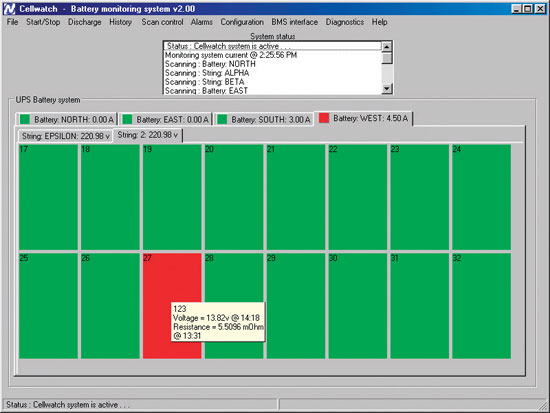

Figure 1. Modern battery monitoring systems can show at a glance if a battery parameter exceeds a threshold and

requires further investigation. This screen shot shows a string of 40 jars with one in alarm mode (red).

The Alternative

A permanently connected monitoring system can replace

the hordes of workers needed to manually monitor batteries

in low-cost labor regions, with additional benefits.

The first step is to install a battery monitoring system and

understand how it works and how to use it. Knowing how

to adjust it when necessary is critical.

But can the monitoring system tell an organization

anything useful about the future?

The answer requires thinking about the periodicity of

the measurements and what parameters the monitoring

system measures. A permanently

wired battery-monitoring system

would be better

than a handheld device carrying out the same tests every three months

because variability of connections and doubt concerning

the state of the test leads would be removed from the equation.

But why stop at quarterly tests? Surely the more data

points the wired system can gather and compare the better

the detail. More detail helps identify problems earlier

before batteries fail.

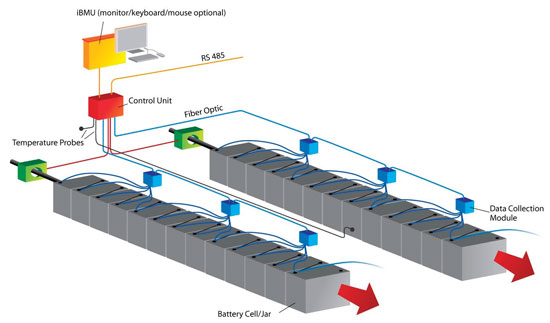

Figure 2. A permanently wired battery monitoring

system featuring data collection modules (DCM) attached

to each battery cell/jar. Each DCM is connected by fiber optic cable to

a control unit that transmits data to a dedicated PC (iBMU). Modern systems

will also expand to include generator and switch gear/telecom batteries.

Ideally, a permanently wired battery-monitoring system

enables readings of the float voltage of every component

of the battery every day. That includes every

cell, block, jar, or even smaller

minimum changeable component

of the battery. If over several

days the float voltage of a cell

trends downwards compared to

others on the string, the system

has identified a problem. Finding

a problem means that the battery

should be investigated without

panicking. The battery may need

replacing, but other outcomes are

possible.

Figure 3. This installation shows a permanently connected (OV) battery monitoring system installed neatly

onto the battery.

Is the float voltage related to

the performance of the battery?

It can be, meaning that it can also

be unrelated. In general the float

voltage of a bad cell will be lower than its peers. But sometimes

the cell has to have become useless before voltage

alone can be used to identify it. So what then? The answer

is Ohmic Value.

Figure 4. Data collection modules (shown attached at the front side) collect information including Ohmic

Value and voltage data from each battery cell/jar and transmit it to a dedicated PC.

Ohmic Value

Before Ohmic Value, users could measure resistance,

impedance, and conductance. The proper use of these

metrics confused users, leading to a number of white

papers and perhaps even some bad blood between proponents

of competing techniques.

IEEE developed the concept of Ohmic Value (OV)

to clear up the confusion. Ohmic Value is a figure that

indicates how the battery behaves under a small load. The

figure is not an absolute, comparable figure, but a relative

measurement. It is relative to the OV on the battery when

new and the OV of all the other cells in the battery.

Typically OV will rise and be detectible as faulty three

months before voltage falls and is visible as faulty. The

owner of a wired-in system with Ohmic Value has at

least three months better forward vision than a system

that relies only on voltage. The key is to be aware of the

periodicity of OV measurements.

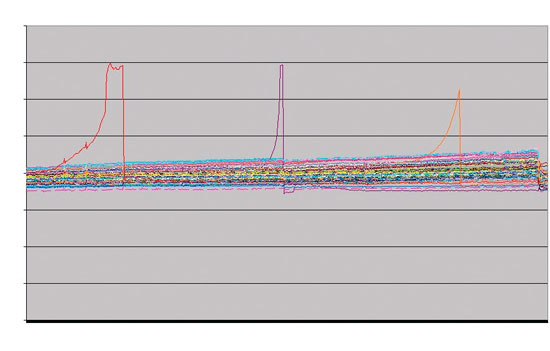

Figure 5. This report shows historical OV data for three years of a battery’s life, including three instances of battery failures and replacements. Notice in particular how much more quickly the

data center manager replaced the faulty jars as time went by.

If 12-volt VRLA blocks can go bad in 14 days, then

OV must be measured, recorded, and compared (analyzed)

every day. This frequency provides sufficient time

to investigate, order, and replace parts before the power

system integrity is put in jeopardy. ‘Every day’ measurement

of OV didn’t become practical until recently. To

measure OV, a current must either be injected into the battery

or removed from the battery for a very specific and

accurately measured amount of time. During this process

voltage readings are taken and compared to voltage readings

taken immediately before the test took place. The

difference between these voltage readings indicates the

Ohmic Value of the cell or battery. Unfortunately removing

a large amount of current from the battery or removing

it for an extended period of time can cause problems

in a parallel/string charging arrangement that can result

in damage to the batteries. To avoid this damage, early

versions of wired systems with OV measurement capability

took readings only monthly or every two weeks. Once

again there is a period during which a battery could fail

and the load could be dropped.

The amount of current used in the test has been the

barrier to more frequent testing. The greater the current

the less frequently the test can take place. So a very

small current would be best. But changes in voltage from

a very small current applied to UPS-sized batteries are

almost impossible to measure, especially with a UPS

charger and inverter running on the same power line.

The electrical noise, ac ripple, and switching pulses

swamp the tiny signal.

Electronic engineers eventually found a way to discriminate

the tiny signals produced by smaller amounts

of current for very short periods of time. This task is still

difficult, especially if the measurement signals are backed

onto the noise output from a UPS and requires a modern,

state-of-the-art battery monitoring system.

A wired system removes the variability of test leads

and the risks of human error, eliminating once and for all

planned “destructive maintenance.” Ohmic scans provide

voltage trending three months earlier than previously possible,

and daily scans identify the day that a battery starts

to trend away from its correct value compared to when it

was new or compared to its peers.

The final detail is that the battery monitoring system

must have the ability to turn itself into a voltage datalogger

the moment the battery goes on-line. This datalogger

then must take a battery reading every few seconds on

each and every cell for the duration of the discharge. Then

it can provide documented evidence of the value of an

investment in a proper wired, predictive, battery monitoring

system that can measure Ohmic Value.